Now that it's clean.

#2

Super Moderator

Join Date: Dec 2017

Location: texas

Posts: 1,202

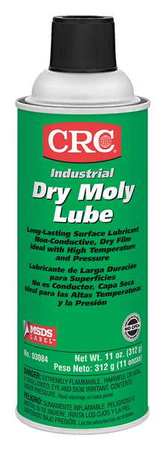

too be fair, I always carefully clean my rifle bores and repeatedly swab the bores after carefully cleaning the bores with a dripping wet ,

repeatedly soaked series of moly soaked swabs

a squeaky clean bore repeatedly swabbed with moly builds a micro surface like greased glass thats perfect for cast bullet use.

Ive used the process on rifles shooting jacketed, cast and black powder, loadings,

regardless of rifle type, theres always been a noticeable improvement in ease of cleaning and usually accuracy,

after several repetitive cleaning and swabbing sessions.

because black powder is corrosive Id follow the moly with a good gun oil on a swab,

to prevent moisture reaching the bore surface (I do that with all rifles)

http://www.engineersedge.com/lubrica...cteristics.htm

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.

http://garage.grumpysperformance.com...41/#post-84978

repeatedly soaked series of moly soaked swabs

a squeaky clean bore repeatedly swabbed with moly builds a micro surface like greased glass thats perfect for cast bullet use.

Ive used the process on rifles shooting jacketed, cast and black powder, loadings,

regardless of rifle type, theres always been a noticeable improvement in ease of cleaning and usually accuracy,

after several repetitive cleaning and swabbing sessions.

because black powder is corrosive Id follow the moly with a good gun oil on a swab,

to prevent moisture reaching the bore surface (I do that with all rifles)

http://www.engineersedge.com/lubrica...cteristics.htm

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.

http://garage.grumpysperformance.com...41/#post-84978

Last edited by hardcastonly; 08-05-2019 at 04:19 PM.

#3

I use to use the newer version of Rem Oil in the pump spray bottle, I had really good luck with it, But I decided to try something different in my Guns, for no other reason than i wanted to, I had GREAT luck with this Pump spray Rem Oil in my Guns. I stil use it on my Steel Bullet molds etc. it is GOOD Stuff, i tested Sidelock Barrels that i had cleaned, and treated with this stuff, and had sat under my Bed for over a Year, They had Zero signs of Rust. Again, Good stuff in my opinion

I did some pretty extensive research on Oils for my Guns, I watched some Corrosion tests, and Decided to go with this Hoppes Elite T3, Watching a YouTube video test of Gun oils in Salt Spray This Hoppes Elite T3 did STELLAR! I have been using it for about 6 months or so now? I REALLY Like this stuff! This is a VERY Different Oil than the Rem Pump Spray stuff, The Rem Oil stuff i used would eventually Dry on the Surface, This new Hoppes T3 Stays the Same, 6 Months later it stil looks like Fresh Clean Oil on the Surface, I recently ran Fresh patches down my Rifle Bores to check on them? No discoloring of patches, They look just like they Did when i put them away. I like this Hoppes T3 Oil Better than my Old Pump Spray Rem Oil, So Far anyway

https://www.hoppes.com/elite/elite-gun-oil-with-t3

I did some pretty extensive research on Oils for my Guns, I watched some Corrosion tests, and Decided to go with this Hoppes Elite T3, Watching a YouTube video test of Gun oils in Salt Spray This Hoppes Elite T3 did STELLAR! I have been using it for about 6 months or so now? I REALLY Like this stuff! This is a VERY Different Oil than the Rem Pump Spray stuff, The Rem Oil stuff i used would eventually Dry on the Surface, This new Hoppes T3 Stays the Same, 6 Months later it stil looks like Fresh Clean Oil on the Surface, I recently ran Fresh patches down my Rifle Bores to check on them? No discoloring of patches, They look just like they Did when i put them away. I like this Hoppes T3 Oil Better than my Old Pump Spray Rem Oil, So Far anyway

https://www.hoppes.com/elite/elite-gun-oil-with-t3

#4

Makes no difference to me whether it is BP & Subs or BH.

It seems everybody develops their own method....

One thing that I would highly suggest - do not use any petroleum products in the bore. Montana Ex-treme is a fully synthetic oil.

Last edited by sabotloader; 08-05-2019 at 05:23 PM.

#6

Yep i sure do! Just a Few Good Tight Fitting patches down the Bore. With Nipple Removed, i use my Air Nozzle from my Compressor and BLAST Air Through the nipple hole, This Forces oils from the Breech up in to the Bore, Then another Couple of Tight fitting Patches back down the Bore to pick up any Oil i Blew out of the Breech Area.

I take it 1 step farther when preparing to load a Rifle for Hunting, I do the EXACT Same procedure above, But i also use a 1/4-28 Magspark 209 Nipple and Pop 1, maybe 2 Federal 209A Primers Straight Through (These are HOT 209s!!) Then i run 1 Dry patch Down, You will get a LOT of Black Soot on that Patch From the 209s, Then i CONFIDENTLY Load the Rifle to Hunt. This mimics/simulates a Foul Bore BEAUTIFULLY, My Cold Clean Bore Shot is DEAD ON using this Method

#7

Fork Horn

Join Date: Jul 2019

Location: SE CT

Posts: 145

Idaholewis: The next time you are about to fire off the 209 primer, try running a dry patch down the bore and leave it there with the ram rod. The black soot from the primer, and any remaining oil in the breech will be transferred to the patch for easy removal. Not much different from your method, but it has worker for me and I feel confident that all of the oil residue has been picked up. Give it a try to see if you like the results.

#8

I will say...……… I'm now using another part of your methods..... WINDEX w/ammonia D.

I found the first time cleaning my muzzle brake was a complete PITA. I'm friends with the designer/builder, so I asked him about the best way to clean the brake.

"Windex Original. Just spray the brake, let it set for 30sec or so, then continue to spray the brake clean. Dry and lubricate the brake well".

Works perfectly and just that easy